- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Warehouse Automation

- Industrial Conveyor Systems

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

- D-Tools

- Careers

- Chat Live

- Blog

- Literature & Manuals

- Products

- Solutions

- Applications

- Accumulation

- Controls Solutions

- Custom Systems

- Depositing & Rejects

- Elevations & Line Egress

- Indexing & Positioning

- Inspection & Testing

- Merge, Diverting and Sorting

- Product Flow & Control

- Product Handling

- Rotating Conveyors

- Industrial Conveyor Systems

- Warehouse Automation

- Lean Manufacturing and Warehousing

- Inline Labeling and Printing Conveyors

- Engineered Solutions

- Applications

- Industries

- Parts & Services

- Distributors

- Resources

- About Us

Food Grade Conveyor Belts for Food Handling and Processing

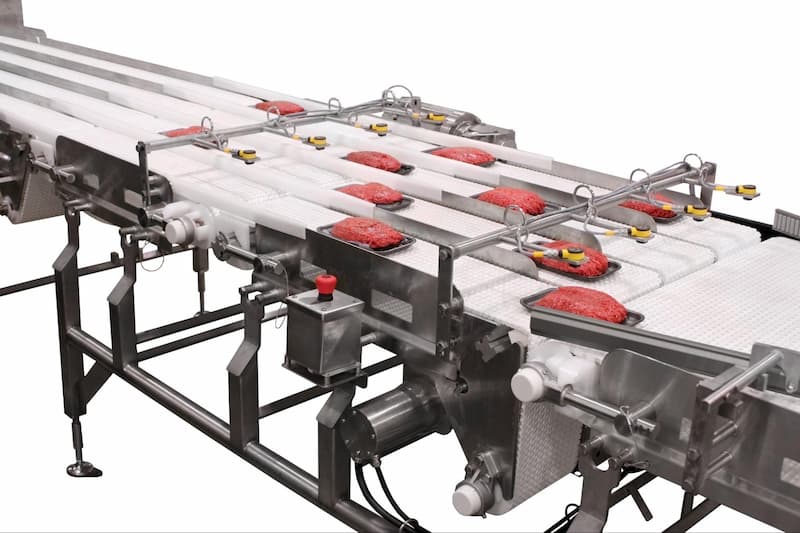

Dorner’s world-class food handling and processing conveyors are highly sanitary and built to operate at high speeds. These conveyors have earned a stellar track record in helping businesses maximize their efficiency and productivity levels in achieving their full potential.

If your business requires a custom conveyor belt for food processing, Dorner is uniquely positioned to develop specially made systems that meet our customers’ vision for enhanced workflow.

Benefits of Dorner’s Food Handling and Processing Sanitary Conveyors

High Sanitary Standards

Conveyor Belt Food Safety Commitment

- Hygienic Design

- Ease of Sanitation

- Effective Sanitation

- Ease of Disassembly

- Operator Safety

Custom Solutions for Unique Systems

Dorner Food Conveyor Belts Provide Safety Beyond Your Products

- BISSC (Baking Industry Sanitation Standards Committee)

- FDA (U.S. Food and Drug Administration)

- RoHS (Restriction of Hazardous Substances)

- CE (Conformité Européenne)

- OSHA (Occupational Safety and Health Administration)

- ANSI (American National Standards Institute)

Sanitary Food Conveyors Applications

Accumulation & Cooling

Inspection & Metal Detection

Washing & Sorting

The right sanitary conveyor makes washing and sorting certain products, like fresh produce, a breeze. Designed for easy cleaning, our AquaPruf conveyors can safely and effectively endure the washing and sorting process without compromising your product’s quality or risking damage to the conveyor system.

Packaging

Conveyors for Food Processing in Every Category

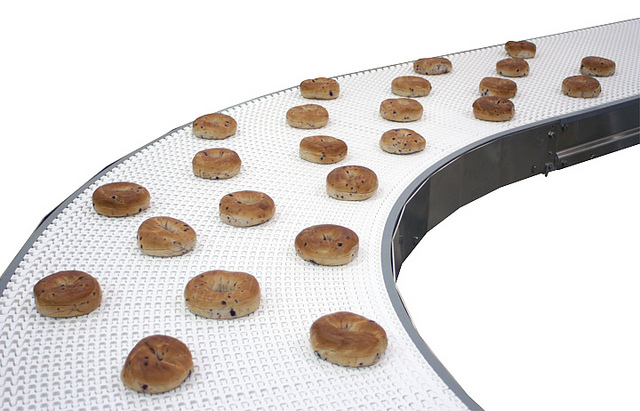

Baking & Confectionary

- Bread

- Cookies

- Pies

- Chocolates

- Gum

- And more!

Dairy & Cheese

Whether you are working with blocks of cheese, individual slices, or other dairy products, our conveyor belts for food manufacturers can help move your product down the line with accuracy and minimal damage.

- Bread

- Cookies

- Pies

- Chocolates

- Gum

- And more!

Meat, Poultry & Seafood

Ready-To-Eat Foods

Produce

See Dorner’s Conveyors for Food Processing and Handling in Action

Custom Material Handling Equipment for Food

When your business needs a specially made solution, you can count on Dorner! As a leading-edge commercial food processing equipment manufacturer, Dorner is known for creating custom food processing services and equipment for our customers.

- Belt scrapers

- Guiding

- Conveyor covers

- Drip pans

- Deviators

- Automated controls

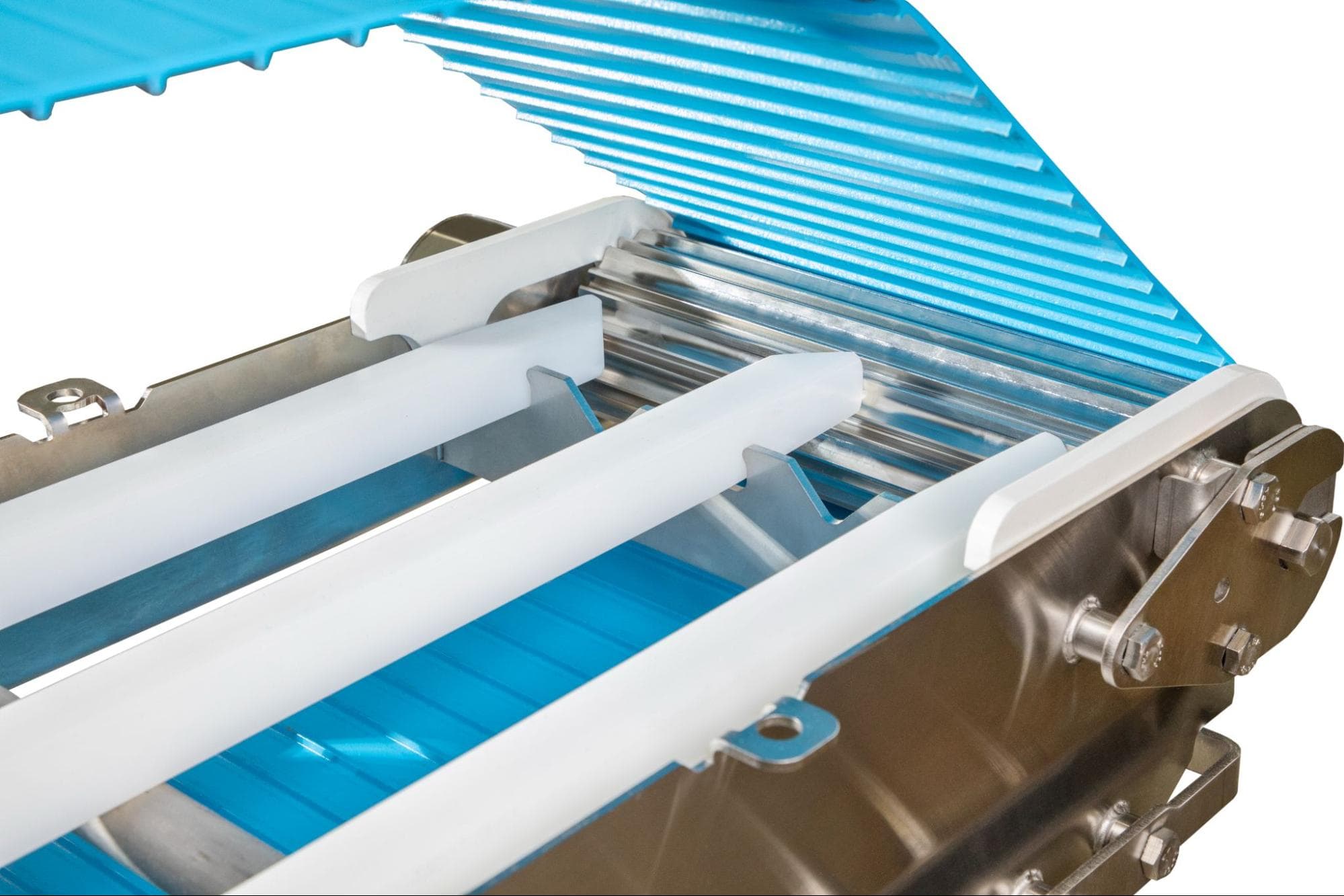

Dorner’s AquaPruf Industrial Food Grade Conveyors Boast Innovative Design

Hygienic Designs

LESS WORRY ABOUT YOUR PRODUCT QUALITY

- Tool-less disassembly

- Cleaning prep in under a minute, complete disassembly in less than 3 minutes

- Optional frame cut-outs and belt lifters for continuous access to inside of the conveyor

- Tip-up tails allow for quick release of belt tension

- Continuous TIG-welded 304 stainless steel frame

CONFIDENCE IN YOUR FOOD HANDLING EQUIPMENT

- BISSC & USDA certified conveyors

- FDA approved materials and components

Built for Demanding Environments

AquaPruf Ultimate Conveyor Benefit Highlights

- All surfaces on internal frame components are polished to 32 microinch, except belted product.

- All bearings are external to the conveyor and a minimum of 25 mm away from the food zone.

- Drive sprocket design includes a quick cleaning system to ensure cleaning can be done below the sprocket surface.

- Patent pending idler tail cleaning system on Modular Belt and Positive Drive Belt models.

- Belting / Chain meet strict 3-A, and USDA requirements.

- All support stands use only sanitary threadless feet designs.

- Radii on all internal components meet the 6 mm (0.25″) standard requirement.

Food Conveyor Belt Installation Services

Commercial Food Processing Equipment Services for Dorner Conveyors

Training Services

Maintenance Program

Dorner's Food Handling and Processing Conveyors

AquaPruf Conveyors

- Tool-less disassembly. Cleaning prep in under a minute, complete disassembly in less than 3 minutes

- Optional frame cut-outs and belt lifters for continuous access to inside of the conveyor

- Tip-up tails allow for quick release of belt tension

- Continuous TIG-welded 304 stainless steel frame

- Spiral cam belt tensioning with patent pending thread-less design

- Patented sprocket alignment key

- Gearless, oil-free iDrive2 sanitary motorized roller

AquaPruf Ultimate Conveyors

- All surfaces on internal frame components are polished to 32 microinch, except belted product.

- All bearings are external to the conveyor and a minimum of 25 mm away from the food zone.

- Drive sprocket design includes a quick cleaning system to ensure cleaning can be done below the sprocket surface.

- Patent pending idler tail cleaning system on Modular Belt and Positive Drive Belt models.

- Belting / Chain offered meet strict 3-A, and USDA requirements.

- All support stands use only sanitary threadless feet designs.

- Radii on all internal components meet the 6 mm (0.25″) standard requirement.

- Conveyor cleaning guideline is provided specifically for effective cleaning of the Dorner product.

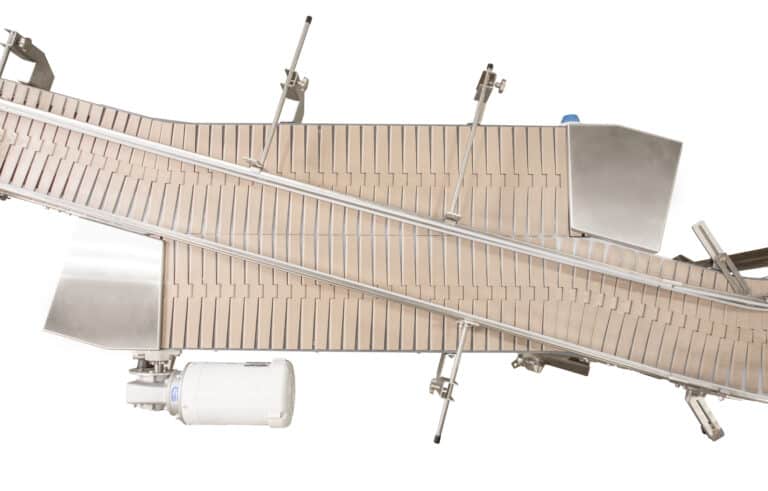

AquaGard LP Conveyors

- Quick five-minute belt change for increased uptime

- Compact and enclosed tensioning system providing smooth and snag-free cleaning

- 304 stainless steel frame, head and tail plates

- V-Groove frame with guided belt ensures accurate tracking

- Tip-up tails for access inside the conveyor for cleaning and maintenance

- Streamlined design fits where other conveyors do not

- Low-profile, operator safe design with no pinch points

- Small 1.25 in (32 mm) diameter rollers for transfer of small products

- A variety of FDA approved belting to meet application needs

AquaGard GT Conveyors

- Best for: packaging, bottling, dry food processing, part handling, long lengths, accumulation and buffering

- Smooth frame design for ease of cleaning

- Capable of multiple curves as well as inclines and declines on a single conveyor

- Bolt together construction for modularity and future add-ons

- Innovative transfer options

- Powered transfers

- Side transfer modules

- Inline transfer modules for high speed applications

AquaGard 7350 Conveyors

- Rugged and Durable Design

- 304 Stainless Steel frame features open design with minimal horizontal surfaces

- Designed for wipe down and low pressure wash-down with non-caustic chemicals

- V-guided belt tracking on belted models

- Tip-up tails for access inside the conveyor for cleaning and maintenance

- Safest chain in the industry with chain openings less than 4 mm even on curves

- Unique chain design virtually eliminates friction providing capacity for up to 4 curves on a single conveyor

Stainless Steel Food Conveyor

Space Saving Food Handling Equipment

Food Grade Conveyor Comparisons

When it comes to choosing a food grade conveyor system, Dorner is the leading option, and there are a few key differences that sets Dorner apart as the top choice for food processors.

Sanitation and Cleanability

Customization Options

Conveyor Performance

Global Support and Service

Experience and Expertise

Adding to the Conversation: Make Or Buy?

Food Grade Conveyor Comparisons

History of Food Grade Conveyors

The Introduction of the Modular Conveyor System

Today’s Food Grade Conveyors

Customized Food Processing Solutions from Dorner

Components of Stainless Steel Food Grade Conveyors

- Conveyor frame: The frame is the backbone of the conveyor system, providing structural support for all other components. It is typically made from stainless steel tubing or sheet metal, with a smooth, polished finish that is easy to clean and sanitize.

- Conveyor belt: The belt is the surface on which the food products are transported. Food grade conveyor belts are made from materials that are non-toxic, non-absorbent, and resistant to bacteria growth, such as stainless steel mesh, plastic modular belts, or specialty materials like silicone.

- Drive system: The drive system consists of a motor, gearbox, and sprockets that power the conveyor. The motor and gearbox are typically enclosed in a stainless steel housing to protect them from moisture and contaminants, while the sprockets are made from stainless steel or food-grade plastics and are designed to be easily cleaned.

- Supports and pulleys: Supports, such as legs and brackets, hold the conveyor frame in place and ensure proper alignment. Pulleys guide and support the conveyor belt, with food-grade bearings that allow for smooth rotation. Both supports and pulleys are made from stainless steel for durability and easy cleaning.

- Accessories: Food grade conveyors may include various accessories depending on the specific application, such as guides, dividers, or side walls to keep products in place, or cleaning systems like scrapers or brushes to remove debris from the belt.

Food-handling conveyors are available in a wide range of configurations to suit different food processing applications. Some common types include:

- Belt conveyors: These conveyors use a continuous, flat belt to transport products and are suitable for a wide range of food items, from raw ingredients to finished packaged goods.

- Modular belt conveyors: These conveyors feature a belt made up of interlocking plastic modules, allowing for easy customization and replacement of damaged sections.

- Vibratory conveyors: These conveyors use vibration to move products along a stainless steel trough or channel, and are often used for delicate, fragile, or bulk food items.

- Bucket elevators: These conveyors use a series of buckets attached to a chain or belt to scoop up and elevate food products, such as grains or powders.

- Spiral conveyors: These conveyors feature a spiral-shaped belt that allows for vertical transportation of food products in a compact space.

Understanding Food Handling Conveyor Belt Materials and Customization Options

- PVC (Polyvinyl Chloride): A versatile and economical choice for general purpose food handling.

- Rubber: Offers superior gripping and durability, ideal for heavy or oily products.

- Plastic modular belting: Provides enhanced cleanability and allows for tight transfers and small product handling.

- Urethane: Resistant to cuts, tears, and abrasion, suitable for heavy-duty food processing.

- Wire mesh: Optimal for draining, cooling, freezing, or cooking applications, as it allows for maximum airflow.

Specialty Conveyor Configurations

- Waterfall conveyors: Designed for even distribution of glazes, icing, and coatings over products.

- Diverging conveyors: Used to split product flow into multiple streams for sorting or distribution.

- Vibratory conveyors: Ideal for seasoning, breading, or de-clumping applications, as vibration promotes even coverage and separation.

- Incline/decline conveyors: Used to transport goods between different elevations within a processing facility.

- Spiral conveyors: Designed to minimize floorspace by utilizing vertical space for product accumulation or cooling.

Conveyor Add-Ons and Accessories

- Brushes: Used for product stability, orientation, or cleaning during transport.

- Conveyor rollers: Can be gravity-driven or powered, used for accumulation or product transfer.

- Guide rails and side walls: Provide product containment and prevent spillage or damage.

- Metal detectors and X-ray systems: Integrated for contamination monitoring and quality control.

- Air blowers and filters: Used for removing moisture or debris from products during conveying.

Global Availability

Staying Compliant In Food Grade Processing & Handling

Food Safety Modernization Act (FSMA) Compliance

- Hygienic design principles to minimize contamination risks

- Easy disassembly and cleaning to support effective sanitation

- FDA-approved materials and lubricants to prevent contamination

Global Food Safety Initiative (GFSI) Standards

- Cleanability: Our conveyors are designed for easy cleaning and sanitation, with minimal catch points and crevices where bacteria can grow.

- Material safety: We use only FDA-approved materials and lubricants, ensuring that our conveyors do not introduce any hazardous substances into the food processing environment.

- Traceability: Our conveyors are fully traceable, with detailed documentation of materials, components, and manufacturing processes.

Automation and Industry 4.0

- Robotics: Our conveyors can be equipped with specialized features, such as pallet handling and product positioning, to support robotic pick-and-place operations.

- Sensors and IoT: We can incorporate sensors and IoT devices into our conveyors to monitor performance, detect anomalies, and enable predictive maintenance.

- Data analytics: Our conveyors can feed data into your production management systems, providing valuable insights into throughput, efficiency, and quality control.

Global Food Safety Initiative (GFSI) Standards

- Energy-efficient motors and drives that reduce power consumption

- Lightweight, low-friction belting materials that minimize energy losses

- Modular, reconfigurable designs that allow for easy adaptation to changing production needs, reducing waste and obsolescence

History of Food Grade Conveyors

The history of food grade conveyors is closely tied to the evolution of the food processing industry. As the demand for safe, efficient, and cost-effective food production grew, so did the need for specialized conveyor systems to meet the stringent requirements of food processing environments.

One of the earliest types of food grade conveyors was the roller conveyor, which utilized a series of motorized rollers to transport food products along a linear path. These conveyors were often constructed using materials such as stainless steel and food-grade plastics, which were resistant to corrosion and easy to clean.

The cost of these conveyors varied depending on factors such as the length of the conveyor, the type of rollers used, and the degree of customization required.

As technology advanced, new types of food grade conveyors emerged, such as the webbing conveyor, which used a continuous belt made of food grade materials to transport products. These conveyors often featured cleated surfaces to prevent products from slipping or sliding during transport, and they could be configured to operate at various angles, including inclines of up to 180 degrees.

The Introduction of the Modular Conveyor System

Another important development in the history of food grade conveyors was the introduction of the modular conveyor system. These systems consisted of interchangeable components, such as conveyor belts, pulleys, and tensioners, which could be easily assembled and reconfigured to meet the specific needs of a given application. This modular approach allowed food processors to customize their conveyor systems to suit their unique requirements, while also reducing the cost and complexity of maintenance and repairs.

In recent years, there has been a growing emphasis on using food-grade lubricants and oils in conveyor systems to ensure the safety and quality of food products. Suppliers have responded by developing specialized lubricants that are safe for use in food processing environments and that meet the strict standards set by regulatory agencies such as the FDA.

Today’s Food Grade Conveyors

Today, food grade conveyors are available in a wide range of configurations, from small, portable units designed for use in small-scale food processing operations to large, complex systems that can handle high volumes of product at high speeds. Some of the most common types of food grade conveyors include belt conveyors, roller conveyors, and vertical conveyors, each of which is designed to meet the specific needs of different types of food processing applications.

As the food processing industry continues to evolve, it is likely that we will see further innovations in the design and manufacture of food grade conveyors. From the development of new materials and components to the integration of advanced technologies such as robotics and artificial intelligence, the future of food grade conveyors looks bright, and we can expect to see continued improvements in the safety, efficiency, and cost-effectiveness of these critical components of the food processing industry.

Components of Stainless Steel Food Grade Conveyors

Stainless steel food grade conveyors are essential equipment in the food processing industry, designed to safely and efficiently transport food products through various stages of processing and packaging. These conveyors are constructed using high-quality, stainless steel components that meet strict hygiene and safety standards. The main components of a stainless steel conveyor include:

- Conveyor frame: The frame is the backbone of the conveyor system, providing structural support for all other components. It is typically made from stainless steel tubing or sheet metal, with a smooth, polished finish that is easy to clean and sanitize.

- Conveyor belt: The belt is the surface on which the food products are transported. Food grade conveyor belts are made from materials that are non-toxic, non-absorbent, and resistant to bacteria growth, such as stainless steel mesh, plastic modular belts, or specialty materials like silicone.

- Drive system: The drive system consists of a motor, gearbox, and sprockets that power the conveyor. The motor and gearbox are typically enclosed in a stainless steel housing to protect them from moisture and contaminants, while the sprockets are made from stainless steel or food-grade plastics and are designed to be easily cleaned.

- Supports and pulleys: Supports, such as legs and brackets, hold the conveyor frame in place and ensure proper alignment. Pulleys guide and support the conveyor belt, with food-grade bearings that allow for smooth rotation. Both supports and pulleys are made from stainless steel for durability and easy cleaning.

- Accessories: Food grade conveyors may include various accessories depending on the specific application, such as guides, dividers, or side walls to keep products in place, or cleaning systems like scrapers or brushes to remove debris from the belt.

Food-handling conveyors are available in a wide range of configurations to suit different food processing applications. Some common types include:

- Belt conveyors: These conveyors use a continuous, flat belt to transport products and are suitable for a wide range of food items, from raw ingredients to finished packaged goods.

- Modular belt conveyors: These conveyors feature a belt made up of interlocking plastic modules, allowing for easy customization and replacement of damaged sections.

- Vibratory conveyors: These conveyors use vibration to move products along a stainless steel trough or channel, and are often used for delicate, fragile, or bulk food items.

- Bucket elevators: These conveyors use a series of buckets attached to a chain or belt to scoop up and elevate food products, such as grains or powders.

- Spiral conveyors: These conveyors feature a spiral-shaped belt that allows for vertical transportation of food products in a compact space.

When selecting food grade conveyors for a specific application, it is essential to consider factors such as the type of food product, the required throughput and speed, the available space, and the cleaning and maintenance requirements. Working with a knowledgeable supplier can help ensure that the conveyor system meets all necessary food safety and performance standards.

Understanding Food Handling Conveyor Belt Materials and Customization Options

Food handling and processing conveyors are available with a variety of belt materials to suit different applications. Common belt materials include:

- PVC (Polyvinyl Chloride): A versatile and economical choice for general purpose food handling.

- Rubber: Offers superior gripping and durability, ideal for heavy or oily products.

- Plastic modular belting: Provides enhanced cleanability and allows for tight transfers and small product handling.

- Urethane: Resistant to cuts, tears, and abrasion, suitable for heavy-duty food processing.

- Wire mesh: Optimal for draining, cooling, freezing, or cooking applications, as it allows for maximum airflow.

Customization options for food grade conveyor belts include cleats, sidewalls, and baffles, which help elevate, contain, or guide products during transport. These features are especially useful when conveying lightweight items, bulk goods, or products up inclines.

Specialty Conveyor Configurations

While straight conveyors are common in food handling and processing, specialty configurations are available to accommodate unique layout requirements or product handling needs. These include:

- Waterfall conveyors: Designed for even distribution of glazes, icing, and coatings over products.

- Diverging conveyors: Used to split product flow into multiple streams for sorting or distribution.

- Vibratory conveyors: Ideal for seasoning, breading, or de-clumping applications, as vibration promotes even coverage and separation.

- Incline/decline conveyors: Used to transport goods between different elevations within a processing facility.

- Spiral conveyors: Designed to minimize floorspace by utilizing vertical space for product accumulation or cooling.

Food grade conveyors can be customized in various lengths and configurations to fit specific processing layouts and requirements.

Conveyor Add-Ons and Accessories

To enhance the functionality and performance of food handling and processing conveyors, various add-ons and accessories are available for the machines, such as:

- Brushes: Used for product stability, orientation, or cleaning during transport.

- Conveyor rollers: Can be gravity-driven or powered, used for accumulation or product transfer.

- Guide rails and side walls: Provide product containment and prevent spillage or damage.

- Metal detectors and X-ray systems: Integrated for contamination monitoring and quality control.

- Air blowers and filters: Used for removing moisture or debris from products during conveying.

These accessories can be combined to create all-in-one conveying solutions tailored to specific food processing needs.

Global Availability

At Dorner, our food grade conveyors and replacement parts are available worldwide through international manufacturers, partners, and suppliers. This global presence ensures that food processing companies can access the conveying solutions they need, regardless of their location.

Local conveyor suppliers and support technicians are available in major markets, such as Europe, South Asia, Latin America, and others, to provide assistance with selection, installation, and maintenance. Globally available spare parts and components help minimize shipping times and costs, reducing downtime for food processing operations.

Staying Compliant In Food Grade Processing & Handling

In the ever-evolving world of food processing, staying up-to-date with the latest food safety regulations and industry trends is crucial for maintaining compliance and a competitive edge. At Dorner, we understand the challenges food manufacturers face, and we’re committed to providing conveyor solutions that help our customers navigate the complex regulatory landscape and stay ahead of the curve.

Food Safety Modernization Act (FSMA) Compliance

The Food Safety Modernization Act (FSMA) has transformed the food safety paradigm, shifting the focus from responding to contamination to preventing it. Under FSMA, food processing equipment must be designed, constructed, and maintained in a manner that ensures food safety. Dorner’s food grade conveyors are engineered with FSMA compliance in mind, featuring:

- Hygienic design principles to minimize contamination risks

- Easy disassembly and cleaning to support effective sanitation

- FDA-approved materials and lubricants to prevent contamination

Global Food Safety Initiative (GFSI) Standards

Many food manufacturers are adopting Global Food Safety Initiative (GFSI) standards, such as BRC, SQF, and FSSC 22000, to demonstrate their commitment to food safety and gain a competitive advantage. Dorner’s food grade conveyors are designed to meet or exceed the requirements of these standards, with features like:

- Cleanability: Our conveyors are designed for easy cleaning and sanitation, with minimal catch points and crevices where bacteria can grow.

- Material safety: We use only FDA-approved materials and lubricants, ensuring that our conveyors do not introduce any hazardous substances into the food processing environment.

- Traceability: Our conveyors are fully traceable, with detailed documentation of materials, components, and manufacturing processes.

Automation and Industry 4.0

As the food processing industry embraces automation and Industry 4.0 technologies, conveyors play a critical role in enabling smart, connected production lines. Dorner’s food grade conveyors are designed to integrate seamlessly with other automated systems, such as:

- Robotics: Our conveyors can be equipped with specialized features, such as pallet handling and product positioning, to support robotic pick-and-place operations.

- Sensors and IoT: We can incorporate sensors and IoT devices into our conveyors to monitor performance, detect anomalies, and enable predictive maintenance.

- Data analytics: Our conveyors can feed data into your production management systems, providing valuable insights into throughput, efficiency, and quality control.

Sustainability and Energy Efficiency

Sustainability and energy efficiency are becoming increasingly important in the food processing industry as companies seek to reduce their environmental footprint and operating costs. Dorner’s food grade conveyors can contribute to these goals through:

- Energy-efficient motors and drives that reduce power consumption

- Lightweight, low-friction belting materials that minimize energy losses

- Modular, reconfigurable designs that allow for easy adaptation to changing production needs, reducing waste and obsolescence

By staying at the forefront of industry trends and regulations, Dorner is uniquely positioned to help food manufacturers maintain compliance, competitiveness, and profitability. Our commitment to innovation, quality, and customer success ensures that our food grade conveyors are always aligned with the evolving needs of the food processing industry.

FAQs

What Types Of Lubricants Does Dorner Use In Their Food Grade Conveyors?

We use only NSF and FDA-approved lubricants to ensure the highest level of food safety. The specific category of lubricant (H1 or H2) depends on the application and the potential for incidental food contact.

What kinds of food conveyors are available from Dorner?

We offer a wide variety of food conveyor types to suit your needs, including:

- Belt conveyors (with various belt materials and configurations)

- Modular belt conveyors (for easy cleaning and tight transfers)

- Positive drive conveyors (for precise product handling)

- Metal detectable conveyors (for added safety)

- Specialty conveyors (waterfall, high-speed, vacuum, and more)

What Sanitary Design Options Does Dorner Provide?

We offer three main sanitary design levels to fit your specific requirements:

- AquaPruf. The ultimate in sanitary design, with continuous welding, full washdown compatibility, and a superior finish for optimal cleanability.

- AquaGard. Perfect for applications requiring frequent washdowns, featuring open frame designs, FDA-approved belting, and minimal catch points.

What Materials Does Dorner Use In Their Food Grade Conveyors?

We use only the best materials to ensure optimal sanitation and performance, like 304 and 316 stainless steel for frames, supports, and components, FDA-approved belting materials like polyurethane, PVC, and modular plastic, food-safe lubricants, and specialty materials, including antimicrobial coatings and metal detectable accessories.

What Is a Finger Joint On A Food Processing Conveyor?

A finger joint, also known as a finger splice or hinge splice, is a type of connection used to join two ends of a conveyor belt together in food processing and other industries. This method is particularly common in modular plastic conveyor belts, which consist of interlocking plastic modules that form a continuous, flat conveying surface.

Have more questions? Contact us today to learn more about how Dorner’s food grade conveyors can revolutionize your food processing operation.

Frequently Asked Questions About Dorner’s Food Handling and Processing

What Types Of Lubricants Does Dorner Use In Their Food Grade Conveyors?

We use only FDA-approved lubricants to ensure the highest level of food safety. The specific category of lubricant (H1 or H2) depends on the application and the potential for incidental food contact.

What kinds of food conveyors are available from Dorner?

We offer a wide variety of food conveyor types to suit your needs, including:

- Belt conveyors (with various belt materials and configurations)

- Modular belt conveyors (for easy cleaning and tight transfers)

- Positive drive conveyors (for precise product handling)

- Metal detectable conveyors (for added safety)

- Specialty conveyors (waterfall, high-speed, vacuum, and more)

What Sanitary Design Options Does Dorner Provide?

We offer three main sanitary design levels to fit your specific requirements:

- AquaPruf. The ultimate in sanitary design, with continuous welding, full washdown compatibility, and a superior finish for optimal cleanability.

- AquaGard. Perfect for applications requiring frequent washdowns, featuring open frame designs, FDA-approved belting, and minimal catch points.

What Materials Does Dorner Use In Their Food Grade Conveyors?

We use only the best materials to ensure optimal sanitation and performance, like 304 and 316 stainless steel for frames, supports, and components, FDA-approved belting materials like polyurethane, PVC, and modular plastic, food-safe lubricants, and specialty materials, including antimicrobial coatings and metal detectable accessories.

What Is a Finger Joint On A Food Processing Conveyor?

A finger joint, also known as a finger splice or hinge splice, is a type of connection used to join two ends of a conveyor belt together in food processing and other industries. This method is particularly common in modular plastic conveyor belts, which consist of interlocking plastic modules that form a continuous, flat conveying surface.

Contact Us

Dorner - Global Headquarters

Products

Industries

Quick Links

© 2024 Dorner Mfg. Corp. All Rights Reserved | Privacy Policy