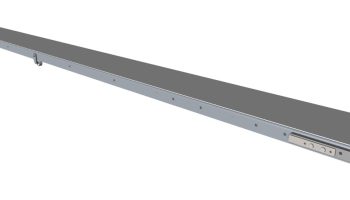

The NEW AquaGard LP Conveyor

Dorner’s new AquaGard LP conveyor is designed to fit in tight spaces, making it the ideal sanitary conveyor for dry or wipedown applications within the packaging, pharmaceutical, confectionary, bakery and other packaged food industries.

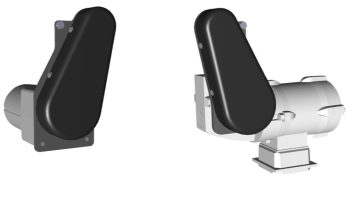

The AquaGard LP (low profile) is the latest reiteration in the AquaGard sanitary conveyor platform. This updated version features a low-profile stainless steel frame with compact 1.25” diameter end-roller pulleys, enabling the conveyor to fit in tight spaces in and around other machinery, as well as safely operate in close proximity to employees. The pulleys also aide in the efficient transfer of small- to medium-sized products on and off the conveyor.

The AquaGard LP’s standard tip-up tail design provides operators complete, easy access to the frame and under the belt for cleaning. Dorner’s reliable V-guided belting ensures precise belt and product tracking along with the enclosed tensioning system keeps the belt to the proper tension and provides smooth snag-free cleaning.

Engineered to meet high sanitary standards, the AquaGard LP has earned the coveted Baking Industry Sanitary Standards Committee (BISSC) certification, which is recognized as the definitive sanitation and safety standards for equipment used in the baking industry.

Features and benefits of the new AquaGard LP conveyor include:

- Widths between 70 mm to 457 mm (2.75 inch to 18 inches)

- Lengths between 700 mm and 5,500 mm (27.5 inches to 18 feet)

- Load capacity up to 22.7 kg (50 lbs.)

- Available in straight configurations; FDA approved belt types: cleated, flat, high friction and others

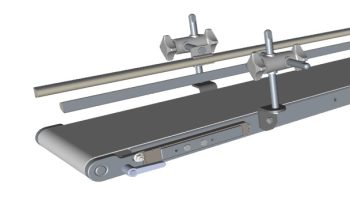

- Toolless, flexible guiding options

Learn more about Dorner’s AquaGard LP.

Common Questions:

Q: What does the “LP” stand for in the name of this new conveyor?

A: The “LP” stands for Low Profile and it distinguishes this conveyor from the other products in the AquaGard line (the 7100 and the 7350)

Q: What type of environment/application is the conveyor designed for?

A: The AquaGard LP carries the same ratings as the AquaGard 7350. It is designed for dry or packaged foods, wet environments and wipe down cleaning using soap and water-based chemicals.

Q: What will happen to the 7200 and 7300 product lines?

A: The 7200 and 7300 will be discontinued and replaced with the newly redesigned AquaGard LP.

Q: How compatible is the AquaGard LP with the 7200 and 7300?

A: The specifications of the conveyor are very similar, and conveyor envelop dimensions are the same allowing the new conveyor to fit in the same places as the 7200/7300. However, parts will not be interchangeable from one platform to the other.

Q: What Belts are available for the AquaGard LP product?

A: Both flat and cleated belts are available. In addition, the AquaGard LP added new FDA approved colored belts to the offering as well.

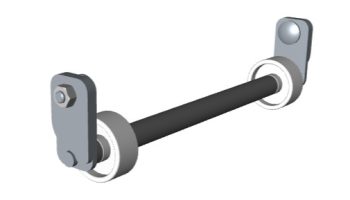

Q: Are wash down greaseable bearings available on the AquaGard LP, similar to the 7300?

A: Not as a standard offering but they are available as an engineered option.

Q: Is V-guided belt a requirement for this conveyor?

A: No, the AquaGard LP can be available with or without V-Guides as standard.

Q: Is the AquaGard LP offered in the same widths and lengths as the 7200/7300?

A: Not exactly. The AquaGard LP conveyor is not offered in 44mm (1.75”) width, but it is available in the new 406mm (16”) width. The conveyor is rated to 50 lbs. and is offered in the same lengths as before; 500mm (20 in) to 5,485mm (18 ft)

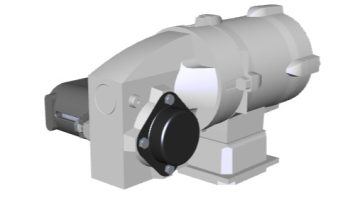

Q: Are all gearmotors still offered as found in the 7200/7300 lines?

A: No, new IP66, 90-degree motors are now available. They are more compacted than the previous NEMA body units; the parallel shafts are the same. Both are available as single speed or VFD controlled.

Q: Does the AquaGard LP use the rack and pinion design for tensioning, similar to 7200/7300?

A: No, the tensioning mechanism is designed with food safety in mind. It uses an enclosed jack screw to tension the belt. The new tip-up tails allow quick and easy access to the underside of the belt and conveyor frame for cleaning.

Q: Is the wet rated heavy-duty chain and sprocket still available?

A: Yes, the heavy-duty sprocket kit is available for both 90-degree and parallel motors.

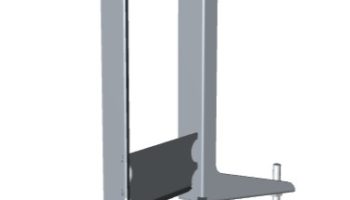

Q: Has the stand design changed?

A: Yes, the stands for this product have been redesigned. The construction is now an open frame welded design. It is made from 7-gauge stainless steel and allows for 60 degrees of incline or decline.

Check out the product page to learn more about the AquaGard LP line and its specifications.